How does telescopic hydraulic cylinders work?

The great advantage telescopic hydraulic cylinders have over any other type of cylinders is their ability to provide an exceptionally long stroke from a compact initial package. The collapsed length of typical telescopic cylinders varies between 20% to 40% of their extended length. Thus, when mounting space is limited, and the application needs a long stroke, a telescopic cylinder is a logical solution.

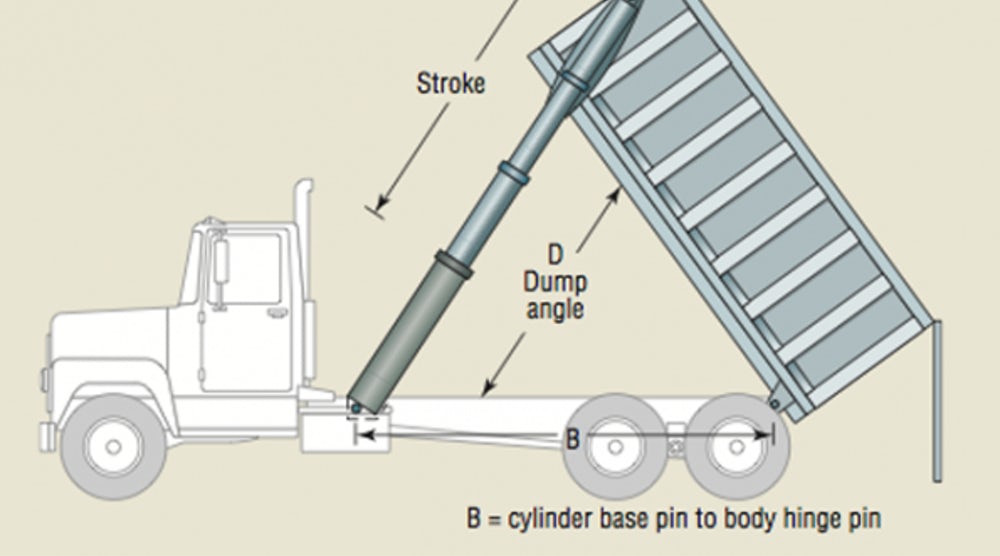

For example, assume a dump body needs to be tilted 60° in order to empty completely. If the body or trailer is fitted with a conventional rod-type cylinder — with a one-piece barrel and stroke long enough to attain that angle — the dump body could not return to a horizontal orientation for highway travel because of the cylinder’s length, even when fully retracted. A telescopic cylinder easily solves this problem.

Telescopic hydraulic cylinders are relatively simple devices, but their successful application requires an understanding of this components’ idiosyncrasies. Knowledge of how telescopic cylinders work and which special application criteria to consider will enable you to design them safely and economically into equipment.

Main and stages

As the name infers, telescopic cylinders are constructed like a telescope. Sections of steel tubing with successively smaller diameters nest inside each other. The largest diameter section is called the main or barrel; the smaller-diameter sections that move are called stages; the smallest stage is also called the plunger. The maximum practical number of moving stages seems to be six. Theoretically, cylinders with more stages could be designed, but their stability problem would be daunting.

Telescopic cylinders normally extend from the largest stage to the smallest. This means the largest stage — with all the smaller stages nested inside it — will move first, and complete its stroke before the next stage begins to move. This procedure will continue for each stage until the smallest-diameter stage is fully extended. Conversely, when retracting, the smallest-diameter stage will retract fully before the next stage starts to move. This continues until all stages are nested back into the main.

Basic types

As with conventional cylinders the two basic types of telescropic hydraulic cylinders are single- and double-acting. Single-acting telescopic cylinders extend under hydraulic pressure and rely on gravity or some external mechanical force for retraction. Single-acting cylinders are used in applications where some form of load is always on the cylinders. The classic single-acting telescopic applications are dump trucks and dump trailers. Pressurized oil extends the telescopic cylinder to raise one end of the dump body. When pressure is released, the weight the dump body forces oil out of the cylinder, it retracts.

Double-acting telescopic cylinders are powered hydraulic in both directions. They can be used in applications where neither gravity nor external force can retract the cylinder. They are well suited to non-critical positioning applications requiring extension and retraction movement of a substantial load.