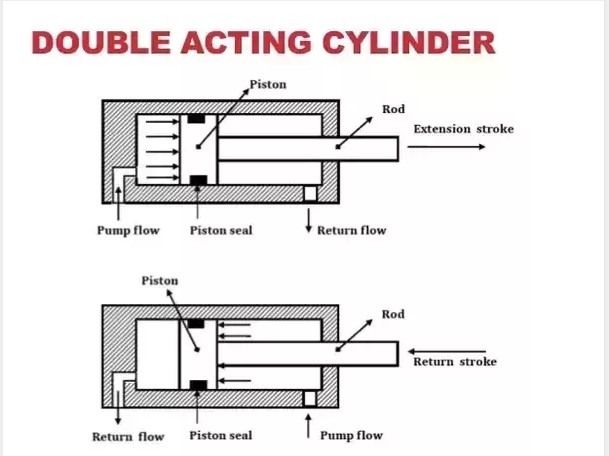

Double acting hydraulic cylinder is a very common hydraulic cylinder type which means both oil ports with oil entering and both directions controlled by oil pressure. When piston rod works, the force of pushing is bigger than pulling, and the piston rubs with the inside barrel thousands of times so if the seal ring is not good enough, leaking will happen after a time, Anbao Group double acting hydraulic cylinder picks the best match for rod and bore and takes clients’ requirements as well. Anbao double acting hydraulic cylinder usually takes superficial treatment to the piston rod like surface hardening or chrome plate to make the surface fine and smooth so that can lengthen the rod’s working life. Besides, As the piston has to fit with the bore accurately, We take special treatment to the seal ring surface so as make it move smoothly.

A double acting hydraulic cylinder is a cylinder where the working fluids act on both sides of the piston alternately. It has a port at its every end; it is supplied with the hydraulic fluid both for the extension as well as retraction of the piston. It is used in the application where there is a requirement of high force in both directions, for example, in steam engines. Bishop is an established and trusted lifting equipment provider having thirty-three years of experience. They provide high efficient double-acting hydraulic cylinder that will help you to manage your power more sustainably, effectively, and safely. Their double acting hydraulic cylinder combines a precision transducer for feedback, a high-performance industrial cylinder, and a controlled valve mounted in one package that reduces the setup time increases the production and eliminates the waste.

we can make a design according to customer’s requirements.If you require our engineer to make a design,please advise us the following specification:

- Rated pressure

- Working pressure

- Test pressure

- Working condition and environment ,for example ,temperature ,working frequency

- Pulling force ,and return stroke force

- Pulling and return speed

- Assembly size

- Seal ring requirements .For example , brand ,seal material etc .

- Tube and piston rod raw material requirements

- Piston rod surface treatment requirements, for example chroming film thickness,Surface hardness etc .

- Painting and other spare parts requirements .

Besides, we also produce hydraulic cylinder tubes and chrome plated rods,if you want to know more ,please contact us on line.