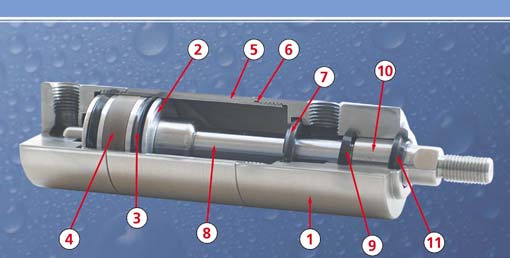

Stainless Steel Body Cylinder

stainless steel cylinder have eliminated the cavities that are present on tie rod cylinders making it the number one choice for food and dairy processing equipment manufacturers. This repairable stainless cylinder is more compact and lower in price.

1. Head & Cap

End caps are precision machined from 303 series stainless steel.

2. Piston

Precision machined from aluminum alloy for reduced weight. Magnets are available for use with proximity switches. A stainless steel piston is optional.

3. Piston Seals

Lip type nitrile are pressure activated and wear compensating for long life.

4. Wear Strip

Teflon and graphite compound for improved wear and side load resistance is standard.

5. Cylinder Tube

Tubing is 300 series stainless steel with a precision honed I.D. and polished O.D.

6. Tube Seal Nitrile o-ring tube seal.

7. Cushions Floating cushion seals optional.

8. Piston Rod

The material is 303 stainless steel. The O.D. is ground and polished and has a .0005″ minimum thickness hard chrome plated surface.

9. Rod Seal

Urethane incorporating a rounded dynamic sealing lip for reduced friction and longer seal life.

10. Rod Bushing

Self lubricating PTFE-based stainless steel bearing.

11. Rod Wiper

Type AN urethane which aggressively removes foreign material from the piston rod and extends rod seal life.